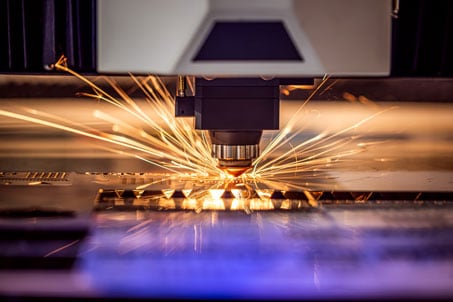

First of all, let me just say that CNC laser cutters are amazing tools. They allow us to create intricate designs and shapes with incredible precision and speed. However, they also pose a significant risk if they are not used properly.

One of the biggest dangers of working with CNC laser cutters is the risk of fire. The intense heat generated by the laser can easily ignite materials that are not meant to be cut or engraved, such as plastic or foam. In addition, dust and debris can accumulate on the machine’s surface and cause a fire if not properly cleaned.

To avoid the risk of fire, it’s important to always keep your work area clean and free of debris. Make sure to properly dispose of any materials that are not meant to be cut or engraved, and use a vacuum or compressed air to clean the machine after each use.

Another danger of working with CNC laser cutters is the risk of eye damage. The laser used in these machines is incredibly powerful and can cause permanent damage to your eyes if you are not careful. It’s important to always wear appropriate eye protection when using a CNC laser cutter, such as safety glasses or a face shield.

In addition to eye protection, it’s also important to wear appropriate clothing when working with a CNC laser cutter. Loose clothing or jewellery can easily get caught in the machine and cause serious injury. Make sure to wear tight-fitting clothing and remove any jewellery before using the machine.

One more thing to keep in mind when working with CNC laser cutters is the risk of electrocution. These machines use high-voltage electricity to power the laser, and it’s important to always follow proper electrical safety procedures when using the machine. Make sure to never touch the machine or its components with wet hands, and always use a ground fault circuit interrupter (GFCI) to protect against electrical shock.

Now that we’ve covered some of the dangers of working with CNC laser cutters, let’s talk about some safety recommendations to help minimise those risks.

First and foremost, it’s important to receive proper training before using a CNC laser cutter. This will ensure that you are familiar with the machine’s capabilities and limitations, as well as how to use it safely and effectively.

In addition to training, it’s also important to read the machine’s manual and follow all safety instructions. Make sure to never modify the machine or its components in any way, as this can lead to serious injury or damage to the machine.

Another important safety recommendation is to always use the appropriate laser settings for the material you are cutting or engraving. Using the wrong settings can not only result in poor quality work, but it can also increase the risk of fire or other safety hazards.

Lastly, it’s important to always have a fire extinguisher nearby when using a CNC laser cutter. In the event of a fire, a fire extinguisher can help to quickly contain the flames and prevent further damage or injury.

In conclusion, CNC laser cutters are incredible tools that offer a wide range of creative possibilities. However, it’s important to always be aware of the potential dangers and to take the necessary safety precautions to protect yourself and those around you. Remember to keep your work area clean, wear appropriate safety gear, follow proper electrical safety procedures, and always use the appropriate laser settings for the material you are working with. With these safety recommendations in mind, you can safely and confidently create amazing designs with your CNC laser cutter.

Cheers,

![]()

Gary’s Safety Tips

Gary’s Safety Tips