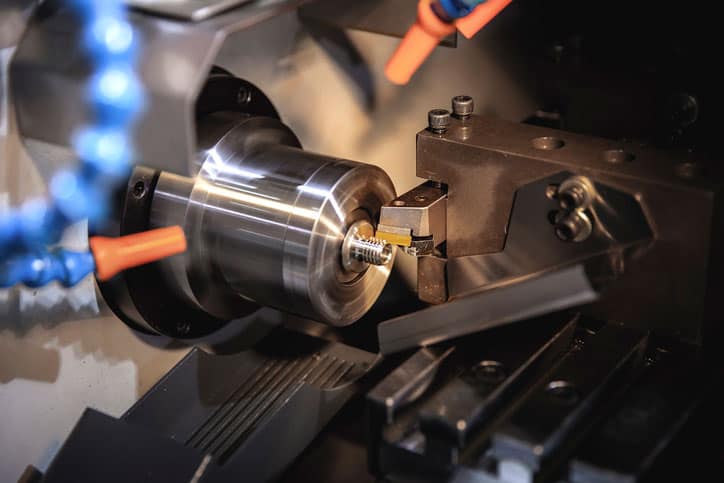

Now, first things first, CNC lathe machines are incredibly powerful tools that can help you produce some seriously impressive results. These machines use computer-controlled systems to precisely cut and shape metal or other materials. However, with great power comes great responsibility, and it’s important to understand the potential dangers involved with using these machines.

One of the biggest dangers of working with CNC lathe machines is the risk of getting caught in the machine. This can happen if loose clothing or long hair gets tangled in the moving parts of the machine. To avoid this, it’s important to always wear appropriate clothing and secure any loose items before starting the machine. Additionally, it’s important to keep the work area clear of any potential hazards that could cause you to lose your balance and fall into the machine.

Another danger to be aware of is the potential for flying debris. As the machine cuts through materials, small pieces of metal or other materials can be thrown into the air at high speeds. To protect yourself, always wear appropriate eye and face protection. It’s also important to keep bystanders away from the work area to prevent them from being hit by any flying debris.

In addition to physical dangers, there are also potential health hazards to be aware of when working with CNC lathe machines. The process of cutting and shaping materials can create fine dust particles that can be harmful if inhaled. To protect yourself, always wear a respirator or mask designed to filter out these particles. It’s also important to keep the work area well-ventilated to prevent the buildup of these particles in the air.

Now that we’ve talked about some of the potential dangers, let’s discuss some safety recommendations to help keep you safe when using a CNC lathe machine. First and foremost, always read the user manual and follow all instructions carefully. The manual will provide you with important information about how to safely operate the machine and avoid potential hazards.

It’s also important to make sure that the machine is properly maintained and in good working order. Regular inspections and maintenance can help identify potential problems before they become serious safety hazards. If you notice any issues with the machine, be sure to address them promptly to keep yourself and others safe.

Another important safety recommendation is to always use the appropriate tools and materials for the job. Using the wrong tools or materials can lead to unexpected accidents or damage to the machine. Before starting any job, make sure you have the right tools and materials on hand and double-check that they are in good condition.

Finally, always be mindful of your surroundings and stay focused on the task at hand. Avoid distractions and stay alert to potential hazards in the area. If you need to step away from the machine, be sure to turn it off and secure any moving parts to prevent any accidental start-ups.

In conclusion, working with a CNC lathe machine can be a rewarding and satisfying experience, but it’s important to be aware of the potential dangers and take appropriate safety measures to protect yourself and others. By following the safety recommendations we’ve discussed today, you can help ensure that your time with the machine is both productive and safe. Thanks for tuning in, and stay safe out there!

Cheers,

![]()

Gary’s Safety Tips

Gary’s Safety Tips