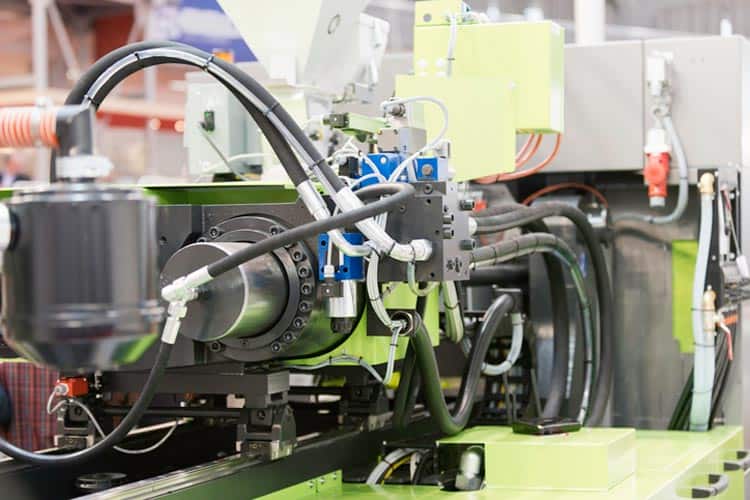

First and foremost, let’s talk about the machine itself. Injection moulders are large, powerful machines that use high pressure and high temperatures to melt plastic pellets and inject them into a mould to create a part. As you can imagine, this process can be quite dangerous if proper safety precautions are not taken.

One of the biggest dangers of working with an injection moulder is the risk of burns. The machine operates at very high temperatures, and if you come into contact with any of the hot surfaces or materials, you can be seriously burned. It’s important to always wear protective gear when working with an injection moulder, including heat-resistant gloves, aprons, and face shields.

Another danger to be aware of is the risk of getting caught in the machine. Injection moulders have moving parts and can be very fast, so it’s important to always be aware of your surroundings and keep a safe distance from the machine when it’s in operation. Make sure to never reach into the machine or try to adjust anything while it’s running.

Electrical hazards are also a concern when working with injection moulders. The machine is powered by electricity and has many electrical components that can be dangerous if not handled properly. Make sure to always follow proper electrical safety procedures, such as turning off the power and unplugging the machine before performing any maintenance or repairs.

Finally, it’s important to be aware of the risks associated with the plastic materials used in injection moulding. Some plastics can release toxic fumes when heated, so it’s important to always work in a well-ventilated area and wear a respirator if necessary. Additionally, some plastics can be flammable, so it’s important to never smoke or use an open flame near the machine.

So now that we’ve talked about some of the dangers of working with injection moulders, let’s discuss some safety recommendations to keep in mind. First and foremost, always make sure to read and follow the manufacturer’s instructions and safety guidelines. These will provide you with important information about how to safely operate the machine and avoid accidents.

Next, make sure to receive proper training before operating an injection moulder. This includes not only learning how to use the machine, but also understanding the risks associated with it and how to properly handle and store the plastic materials used in injection moulding.

It’s also important to perform regular maintenance and inspections on the machine to ensure that it’s in proper working condition. This includes checking for any loose or damaged parts, as well as cleaning and lubricating the machine as needed.

When working with an injection moulder, always wear appropriate personal protective equipment (PPE). This includes heat-resistant gloves, aprons, and face shields to protect against burns, as well as respirators and eye protection to protect against fumes and debris.

Finally, always be aware of your surroundings and keep a safe distance from the machine when it’s in operation. Never reach into the machine or attempt to adjust anything while it’s running, and always turn off the power and unplug the machine before performing any maintenance or repairs.

In conclusion, working with an injection moulder can be dangerous if proper safety precautions are not taken. But by being aware of the risks and following proper safety guidelines, you can stay safe and avoid accidents. So remember, always read and follow the manufacturer’s instructions, receive proper training, perform regular maintenance and inspections, wear appropriate personal protective equipment, and be aware of your surroundings. With these safety recommendations in mind, you can safely and effectively operate an injection moulder and create high-quality plastic parts.

![]()