Introducing our Safe Work Method Statement Template for Turret Punch Press – a helpful tool for ensuring safety in your workplace. Our SWMS template is designed to provide a comprehensive and pre-filled approach to safety for your high-risk machinery project. Here are some key features that make our SWMS template a must-have for your workplace:

- Pre-filled and Comprehensive: Our SWMS template is pre-filled with all the relevant information required for the Turret Punch Press project, ensuring a comprehensive and detailed approach to safety.

- Fully Editable and Customisable: Our SWMS template comes in Microsoft Word format, making it easy for you to edit and customise it to your specific project requirements.

- Includes Scope and Project Details: The template includes a section for scope and project details, ensuring that all relevant information is captured and recorded.

- Includes Checklist of High Risk Machinery: Our SWMS template includes a checklist of any high-risk machinery on-site, ensuring that all safety measures are taken.

- Includes Space for Recording Staff Training: Our template includes a space to record staff training, ensuring that all personnel are adequately trained to operate the machinery safely.

- Includes Before and After Risk Ratings: Our SWMS template includes before and after risk ratings, making it easy to track the effectiveness of your safety measures.

- Includes Resources for Legislative References: Our SWMS template includes resources for use of legislative references, ensuring compliance with relevant regulations and standards.

- Includes All PPE Required: Our template includes all PPE required for the Turret Punch Press project, ensuring that personnel are adequately protected.

- Includes Risk Assessment and Risk Assessment Matrix: Our SWMS template includes a risk assessment and risk assessment matrix, providing a structured approach to identifying and assessing risks.

- Includes Checklist for Implementation: Our template includes a checklist to ensure all requirements have been covered when implementing the SWMS, ensuring no safety measures are missed.

- Includes Sign Off Page: Our SWMS template includes a sign off page for all workers and responsible persons, ensuring accountability and compliance.

- Easy to Use, Easy to Customise: Our SWMS template is user-friendly, making it easy to use and customise to your specific project requirements.

- Suitable for Large Contracts and Tenders: Our SWMS template is suitable for large contracts and tenders, including tier 1 contractual work.

- Instantly Delivered Download: Our SWMS template is available for instant download, allowing you to start implementing safety measures immediately.

In conclusion, our Safe Work Method Statement Template for Turret Punch Press is a helpful tool that ensures safety in your workplace. With all the key features listed above, you can be confident in the safety measures taken for your high-risk machinery project. Order your SWMS template now and take the first step towards a safer workplace.

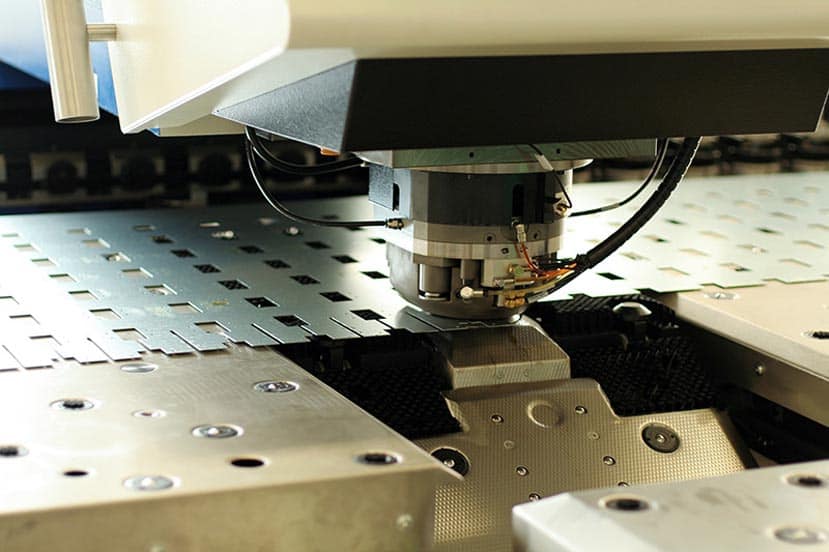

Here is some safety information regarding the turret punch press.

Introduction:

This Safe Work Method Statement (SWMS) outlines the precautions and procedures that must be followed when operating a Turret Punch Press. The purpose of this document is to ensure the safety of workers and others who may be affected by the use of this machine.

Equipment Required:

- Turret Punch Press

- Personal Protective Equipment (PPE) including safety glasses, ear plugs, and gloves

- Material to be punched

- Operating manual

- First aid kit

- Fire extinguisher

Hazards:

- Crushing and pinching hazards from moving parts of the machine

- Electrical hazards from the machine’s electrical system

- Noise hazards from the operation of the machine

- Fire hazards from sparks and hot materials generated during the punching process

- Ergonomic hazards from standing in the same position for long periods of time

Precautions:

- Only trained and authorised personnel should operate the Turret Punch Press.

- Before use, inspect the machine and ensure that all guards are in place, and all components are in good working condition.

- Before starting the machine, ensure that the workpiece is securely clamped to the machine bed to prevent movement during the punching process.

- Wear appropriate PPE, including safety glasses, ear plugs, and gloves.

- Position the machine away from other machinery and obstructions, and ensure that there is sufficient space for movement around the machine.

- Do not wear loose clothing or jewellery when operating the Turret Punch Press.

- Stand clear of the machine during operation, and do not reach into the work area.

- If the machine jams or malfunctions, immediately turn off the power and notify a supervisor.

- Regularly clean the machine and remove any debris that may accumulate during the punching process.

- Do not overload the machine or exceed its capacity.

Emergency Procedures:

- In the event of an emergency, immediately shut off the power to the machine.

- If someone is injured, call for medical assistance immediately.

- If a fire occurs, use the fire extinguisher to put out the fire.

- If an electrical shock occurs, immediately shut off the power and call for medical assistance.

Conclusion:

The Turret Punch Press can be a hazardous machine if not used properly. By following the precautions and procedures outlined in this Safe Work Method Statement, workers can operate the machine safely and avoid potential injuries or accidents. It is the responsibility of all workers to follow these guidelines and report any concerns or issues to a supervisor.

Gary’s Safety Tips

G’day everyone, it’s Gary here, and today I want to talk about a topic that affects many of us in the workplace: compensation for injuries caused by a lack of adherence to Safe Work Method Statements (SWMS).

Let’s be real, accidents happen, but that doesn’t mean we should accept them as the norm. One of the main reasons for workplace injuries is a failure to follow the SWMS. This can occur due to a lack of training, a disregard for safety protocols, or a failure to provide adequate resources to enable workers to adhere to the SWMS.

When an injury occurs due to a lack of adherence to the SWMS, the injured worker has the right to seek compensation. In Australia, the workers’ compensation system provides a safety net for workers who are injured on the job. Workers’ compensation covers medical expenses, lost wages, and other expenses incurred as a result of the injury.

However, workers’ compensation is not always enough, especially when the injury is severe and life-changing. In such cases, the injured worker may be entitled to additional compensation, which can be sought through a common law claim.

A common law claim allows the injured worker to seek compensation for pain and suffering, loss of enjoyment of life, and loss of future earnings. This type of claim is usually pursued when the injury is severe and has long-term consequences, such as permanent disability.

To be successful in a common law claim, the injured worker must prove that their employer breached their duty of care. This means showing that the employer failed to take reasonable steps to ensure the safety of their workers, such as providing adequate training, resources, and equipment.

It’s essential to note that pursuing a common law claim is a complex process that requires the expertise of a personal injury lawyer. A lawyer can assess the strength of the claim, gather evidence, and negotiate with the employer’s insurance company to reach a fair settlement.

Now, let’s talk about the employer’s responsibilities. Under the Occupational Health and Safety Act 2004, employers have a duty of care to ensure the safety of their workers. This duty includes developing and implementing SWMS that are appropriate for the nature of the work.

Employers must ensure that their workers are adequately trained in the SWMS and have access to the resources and equipment necessary to implement the SWMS. They must also monitor compliance with the SWMS and take corrective action when necessary.

If an employer fails to meet their duty of care and a worker is injured as a result, the employer can be held liable. This liability can result in hefty fines, legal fees, and compensation payouts.

But let’s be clear, the goal is not to punish employers. The goal is to ensure that workers are safe and protected. By providing a safe workplace, employers can avoid the physical, emotional, and financial costs of workplace injuries. They can also foster a positive workplace culture that values safety and respect for workers.

In conclusion, injuries caused by a lack of adherence to SWMS can be devastating, but workers have the right to seek compensation. Workers’ compensation is available to cover medical expenses and lost wages, but in severe cases, additional compensation can be sought through a common law claim.

Employers have a duty of care to ensure the safety of their workers, including developing and implementing appropriate SWMS, providing adequate training and resources, monitoring compliance, and taking corrective action when necessary. By meeting this duty, employers can avoid liability and create a safer and more positive workplace culture.

Remember, safety is everyone’s responsibility, and we must all work together to create a workplace that values and protects workers. If you’ve been injured at work due to a lack of adherence to SWMS, don’t hesitate to seek legal advice and pursue the compensation you deserve.

Cheers,

![]()